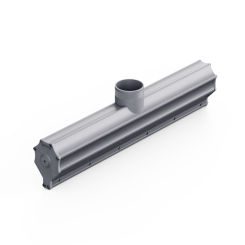

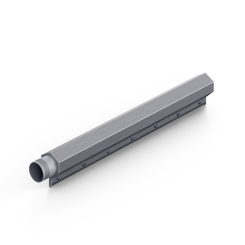

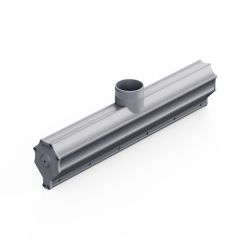

Air Knives

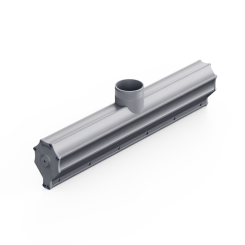

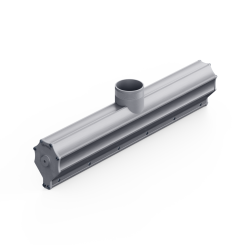

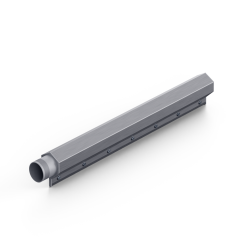

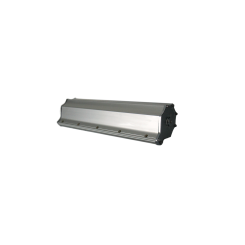

Republic Air Knife Systems use a high velocity air stream to remove liquid, dust, and debris from products prior to labeling, ink jet laser coating, packaging, or other secondary operations. Our air knife systems are available in extruded aluminum or stainless steel with lengths from 2” to 196” with an adjustable gap for better air stream control. Republic's engineering expertise allows us to design and manufacture to-spec systems for hundreds of drying, coating, cleaning, and blow-off applications.

Our Air Knife offerings include:

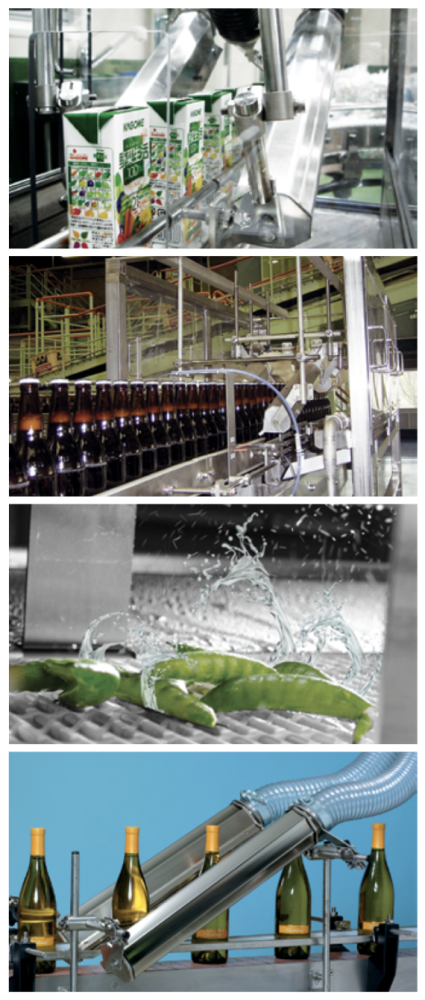

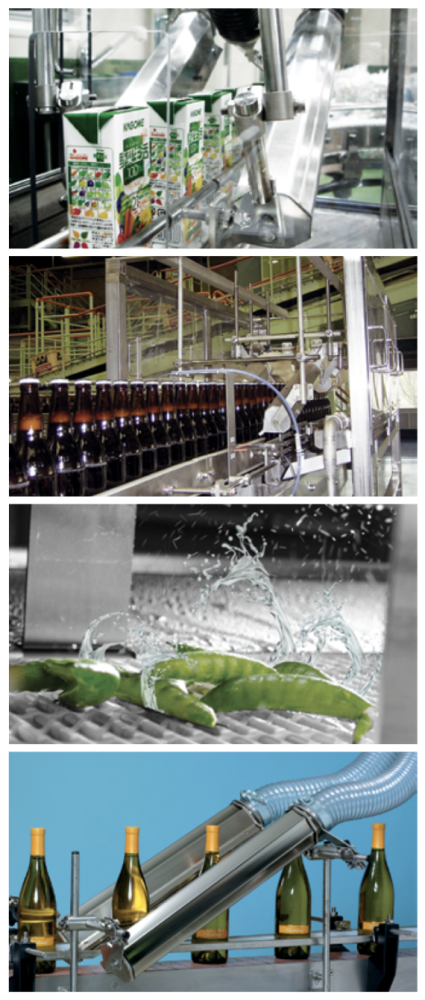

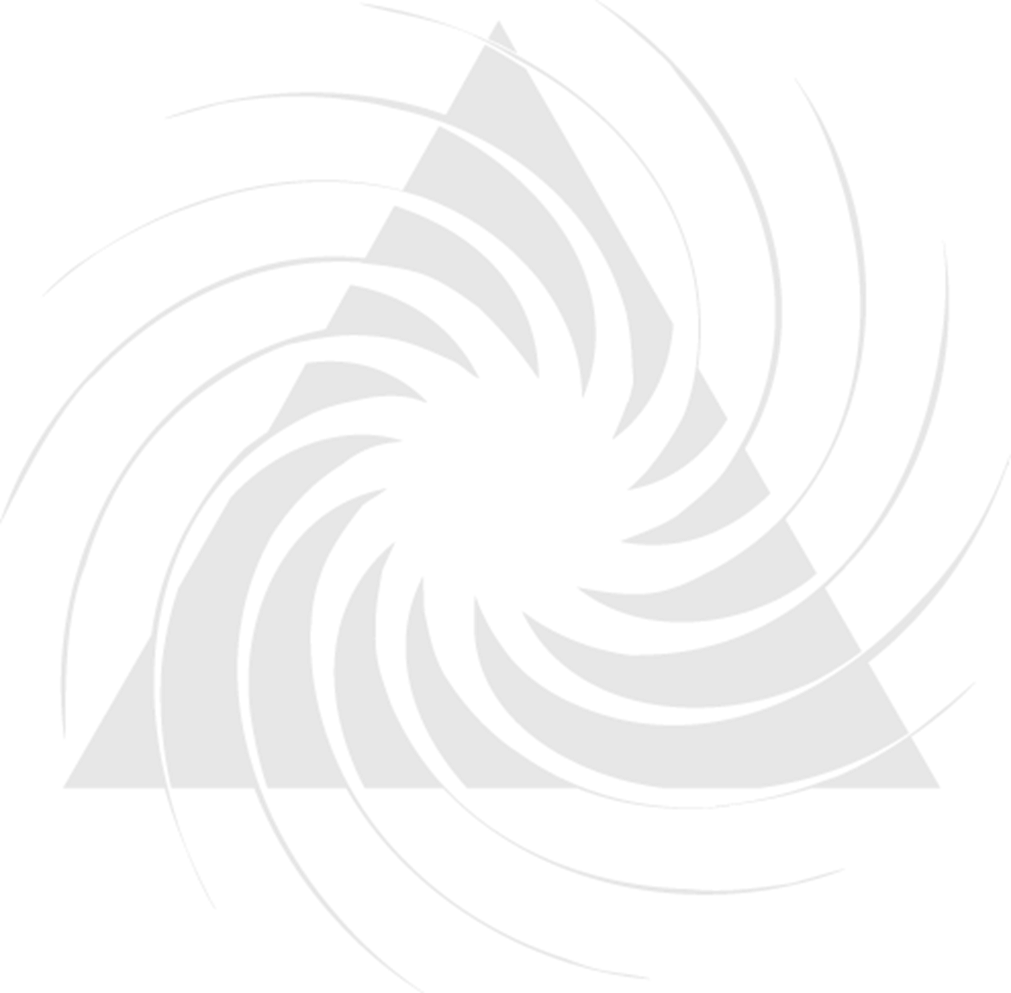

- Standard Can & Bottle Drying Systems

- Aluminum Air Knives and Stainless Steel Air Knives

-

Air Wipes to match your extrusion profile for aluminum, wire, plastic, and more

-

Food-grade Air Knives which are USDA and NSF compliant

-

Custom air knife designs to meet your exact needs. Contact us here!

The breadth of our manufacturing capabilities allows us to engineer and produce any components needed to complete your air knife system, including centrifugal blowers, butterfly valves to adjust pressure and air stream, adjustable air knife mounting brackets, elbows, Y-branches, and manifolds.

ADVANTAGES OF CENTRIFUGAL AIR KNIFE BLOWERS VS. COMPRESSORS

Compressed air can be inefficient and very expensive for drying applications. Generating the necessary flow for most air knife applications with a compressor air system can consume over 12x the energy of a centrifugal blower system.

Consider a compressor air system drying product on a 36"-wide conveyor. Running 24/7, this system will cost over $1,434 per week to operate based on energy consumption. However, a Republic Air Knife System with a centrifugal blower costs only a little over $104 per week to operate.

Our Republic Air Knife Systems are precision-engineered and optimized to operate more efficiently, deliver a higher air velocity, and produce better results than compressor systems. See the “Videos” tab for demonstrations of the power of a Republic Air Knife System. By generating a stronger, more consistent airflow, Republic can help you build the perfect air knife system for your application.

Advantages

- Low energy consumption

- Dry, clean, oil-free air stream

- Filtered blower inlet to prevent particle contamination

- Safe, low pressure

- Increased production speeds and output for a quick return on investment

- Reduced sound levels when compared to compressed air nozzle or round tube design

Available Options

- Aluminum or stainless steel 304 construction

- USDA and NSF compliant food grade stainless steel 316

- Special inlets available including top, side, dual, and extended

- Continuous air slot across the entire length with adjustable gap sizes

- Custom designs available

Drying

- Bottles & cans

- Food products

- Packaging

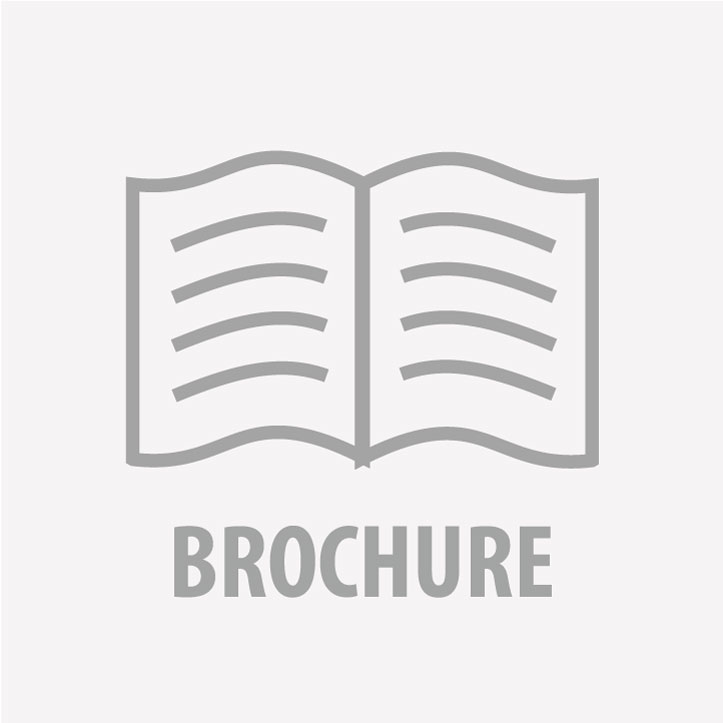

- Fruits & vegetables

- Meat, fish, & poultry

- Textiles & carpeting

- Wire & cable

- Metal

- Tile

- Wood

- Flooring

- Coiled steel

- Hanging parts

- Extrusions, hose, plastics, & film

- Batteries

- Medicine vials

- Stamping, forgings, & machined parts

Belt Cleaning

- Debris removal

- Sawdust removal

- Confectionery removal

- Food topping removal

- Liquid blow-off

Other

- Coating control of food & confectionery topping

- Reduce static

- Remove unwanted liquid

- Keep items from slipping through conveyor belt gaps

- Prevent hot air loss

- Prevent cold air loss

- Coating control of primers, glue, adhesives, & inks

- Crumb removal

- Pan cleaning

Drying

Parts, bottles, cans, food product, packaging, fruits, vegetables, meat, fish, poultry, textiles, carpet, film, wire, cable, metal, tile, wood, flooring, and others.

Watch Republic's air knife system completely dry a long line of soda cans. At :43 seconds, the video then shows a competitor's inferior system at work.

Belt Cleaning

Debris removal, sawdust removal, confectionery and food topping removal, liquid blow-off, and more.

As illustrated in this tile drying application, The Republic Air Knife can be used to shear debris/moisture from any flat surface such as a conveyor belt.

Static Control, Air Curtain, and Many Others

Reduce static, remove unwanted liquid from product, keep items from slipping through conveyor belt gaps, prevent hot air loss from oven, prevent cold air loss from freezer, and many other applications.

Watch Republic's custom air knife system level and recapture icing.

HOW DOES AN AIR KNIFE WORK?

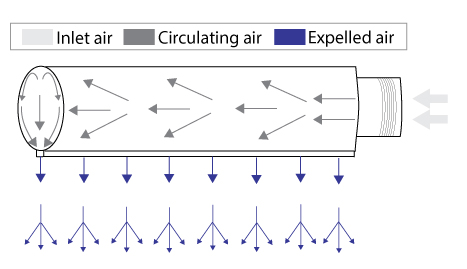

An air knife is an elongated pressurized air chamber, or plenum, with a uniform continuous gap along one edge from which pressurized air exits in an evenly distributed laminar flow, shearing away moisture and/or particulates without mechanical contact.

WHAT IS AN AIR KNIFE USED FOR?

Air knives can be used for a variety of industrial and manufacturing applications, including drying produce, cleaning dust and debris off products or materials before packaging or further processing, removing condensation from canned beverages or other products, removing sawdust, reducing static, and more.

WHAT IS AN AIR KNIFE DRYING SYSTEM?

Apart from the actual air knife made from stainless steel or other materials, an air knife system requires a blower to provide a constant flow of air at a steady pressure. Centrifugal blowers are often used for air knife systems.

HOW DO YOU MAKE AN AIR KNIFE?

Air knives can be manufactured from extruded aluminum, stainless steel, or other materials. Air enters from the inlet on one end of the knife, circulates through the plenum, or main body of the knife, and is forced to exit through a narrow gap which directs the high-impact and high-velocity air in the intended direction. Republic offers air knives in lengths from 2” to 196” with an adjustable gap for better air stream control. In-house engineering expertise allows us to provide a heat source for your high temperature applications or cold air systems for cooling.