Vacuum Hold Down Systems

Republic’s Vacuum Hold Down Kits provide reliable and efficient solutions for securing materials in various fabrication processes, eliminating the need for traditional work-holding methods.

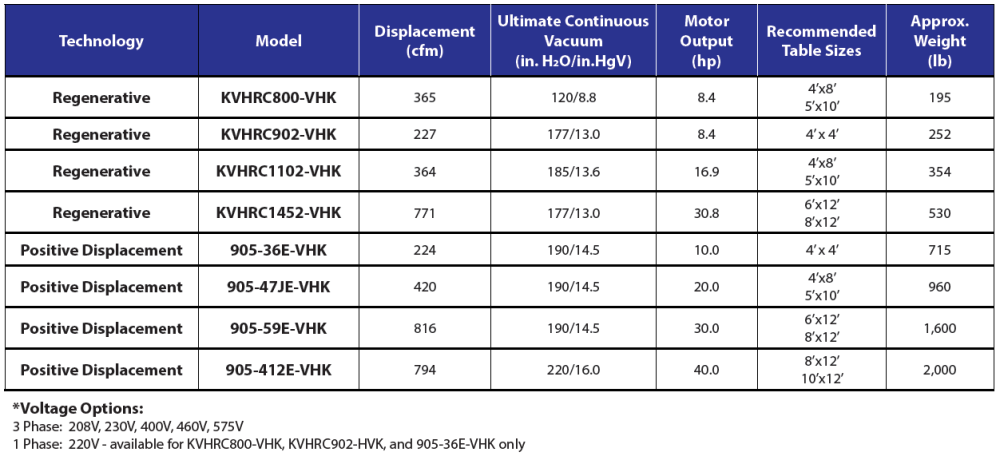

Republic offers two series of Vacuum Hold Down Systems: Regenerative Vacuum Hold Down Kits and Roots Rotary Lobe Vacuum Hold Down Kits. These systems are designed to meet the demanding needs of CNC woodworking, flexible fabric cutting, digital finishing, sign manufacturing, and random-shape cutting applications. Our VHK systems provide fabrication facilities, hobbyists, and CNC machine manufacturers with universal hold down solutions that eliminate the need for screws, clamps, and other cumbersome work-holders, ensuring precision and efficiency in your processes, our VHK systems provide the reliable vacuum hold down capabilities you need to keep materials securely in place.

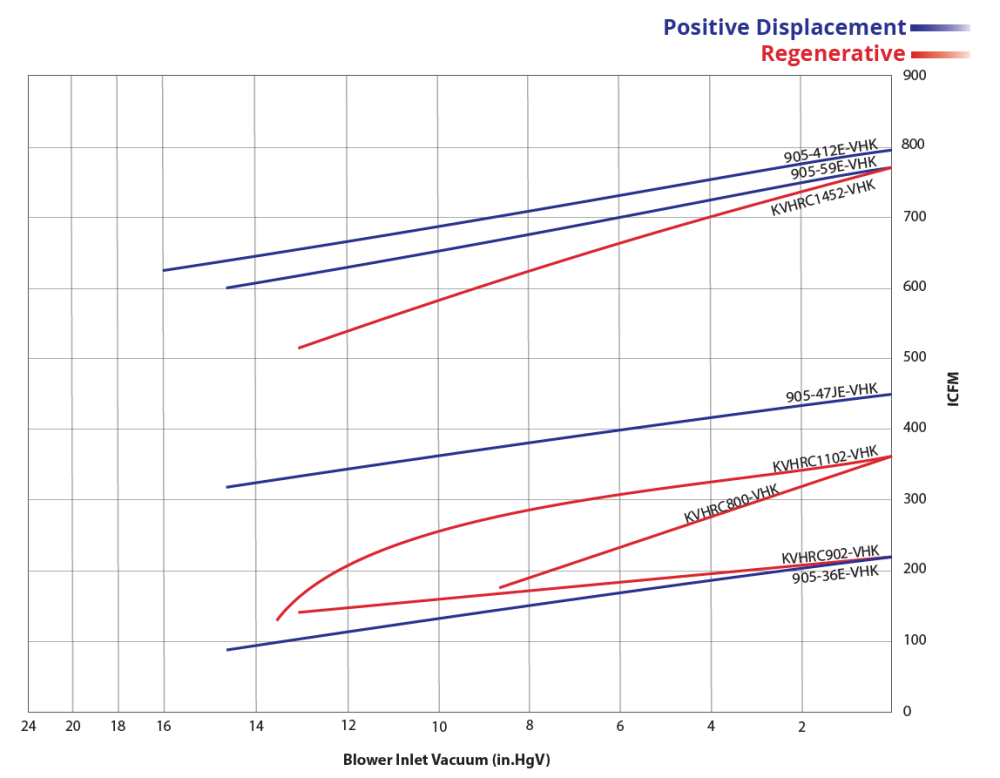

Our Roots Vacuum Hold Down Kits (VHK) are designed to meet the demanding needs of CNC woodworking, flexible fabric cutting, digital finishing, sign manufacturing, and random-shape cutting applications. Our VHK systems provide fabrication facilities, hobbyists, and CNC machine manufacturers with universal hold down solutions that eliminate the need for screws, clamps, and other cumbersome work-holders, ensuring precision and efficiency in your processes. Our VHK systems provide the reliable vacuum hold down capabilities you need to keep materials securely in place, with units capable of providing maximum air flow of 800 CFM and 220” H2O

Our Regenerative VHK systems deliver efficient and consistent vacuum hold down performance, with units capable of providing maximum air flow of 771 CFM and 177” H2O. Our systems are shipped pre-assembled with all necessary components, including the blower, associated plumbing, pre-set spring-loaded vacuum relief valve, inlet filter canister and paper filter element, and PVC or NPT inlet connection. This comprehensive package ensures quick and easy installation, allowing you to get up and running with minimal downtime.