Regenerative Blowers

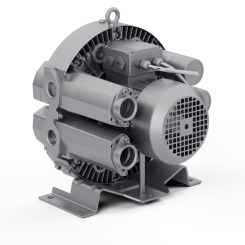

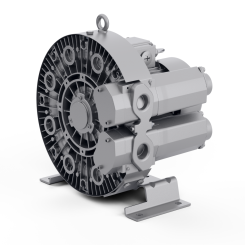

Republic Regenerative Blowers have decades of proven performance across hundreds of pressure and vacuum applications.

Republic Regenerative Blowers are available in single stage (one impeller), double stage (two impeller), or triple stage (three impeller) configurations:

- Air Flow: From 50 cfm up to 776 cfm

- Pressure Capacity: From 47" H2O to 337" H2O

- Vacuum Capacity: From 40" H2O up to 281" H2O

- Motor Grade: IP 44, 54, 55, B/F Class

The impeller is directly connected to the motor shaft and the bearings are outside the compression chamber, ensuring maximum operational reliability under high differential pressure.

Explore our full lineup of Republic Regenerative Blowers, including:

- HRC and 4RC lines of Regenerative Blowers

- Pressure Kits (and Enclosed Pressure Kits)

- Vacuum Kits (and Enclosed Vacuum Kits)

- Vaccum Hold-Down Kits (VHK)

![]()

![]()

Advantages

- Robust & efficient performance

- Compact & lightweight design

- Low noise level

- Integrated TEFC motors

- 50/60 Hz dual frequency

- Horizontal & vertical mounting

- Virtually no maintenance

- Minimal downtime

Available Options

- Pressure kits

- Vacuum kits

- Explosion-proof motors

- Direct coupled packages

- Washdown motors

- Specialty motors

- Enclosures

- Variable frequency drives

- Custom panels

Higher-Endurance & Cooler-Running 2-Stage Blowers

Printing

- Paper transfer

- Excess removal

- Mail sorting

- Punch collection

Bottling/Food

- Bottling

- Food processing

- Labeling

- Feeding

Manufacturing

- Vacuum transfer

- Stamping

- Scrap collection

- Batch processing

- Air bearing

- Furnace efficiency

- Parts processing

- Packaging

Chemical Processing

- Chemical transfer

- Pellets transfer

- Hopper processes

- Aeration

Textile

- Industrial sewing machines

- Automatic loom machines

- Excess cloth removal

- Knitting

Other

- Paper drying

- Conveying

- Dental

- Laundry

- Clean rooms

- Photography

- Spas

- Tank aeration

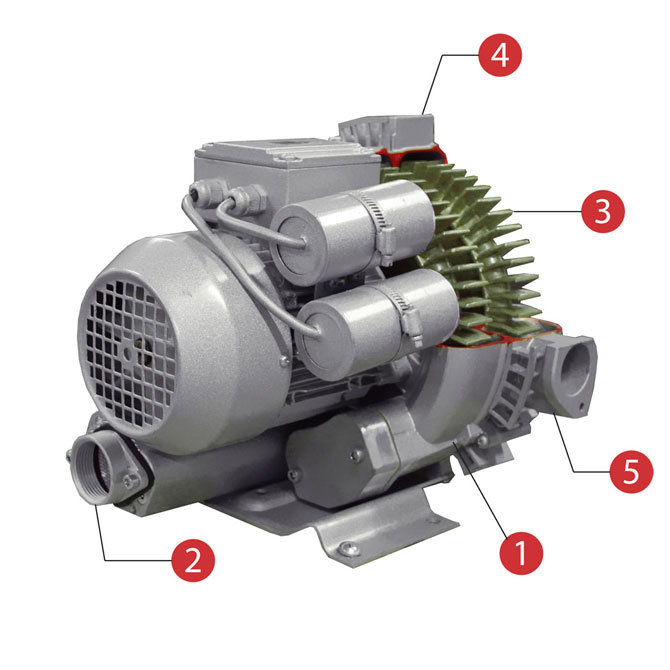

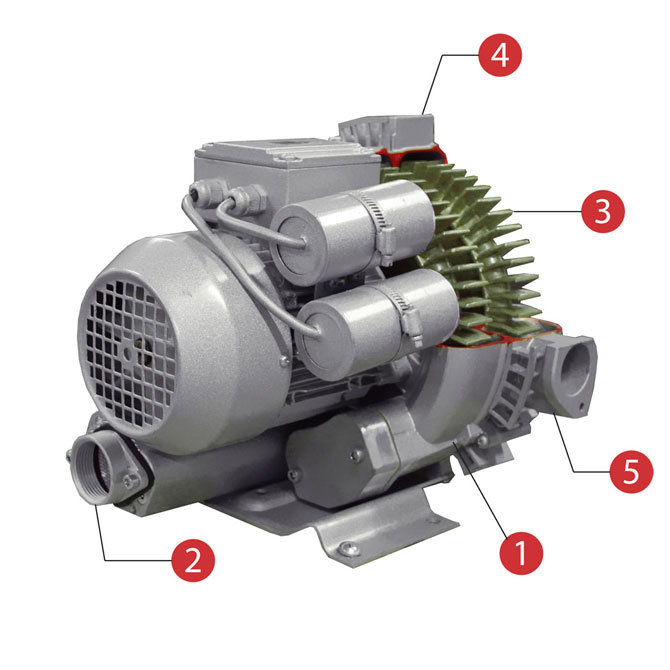

How Does a Regenerative Blower Work?

A regenerative blower, also called a side channel blower or ring compressor, pulls air or gas into a side channel (1) through the air inlet (2). This air is progressively accelerated and pressurized by one or more impellers (3) rotating inside the impeller chamber (4). The resulting pressurized air or gas is discharged through the exhaust outlet (5).

Image

- Side channel

- Air inlet

- Impeller

- Impeller chamber

- Exhaust outlet

- Air Flow: From 50 cfm up to 776 cfm

- Pressure Capacity: From 47" H2O to 337" H2O

- Vacuum Capacity: From 40" H2O up to 281" H2O

- Motor Grade: IP 44, 54, 55, B/F Class

- Explosion-Proof Motor Grade: IP 64,65