Rotary Claw Vacuum Pumps

Efficient and Reliable Claw Pumps for Demanding Industrial Applications

At Republic Claw Pumps are designed to provide deep vacuum (~28"HgV) with exceptional reliability and minimal maintenance requirements. These pumps are ideal for a wide range of applications, including pneumatic conveying, packaging, central vacuum systems (medical or industrial), and food preparation. Engineered with precision and built to last, Republic’s Claw Pumps are the optimal choice for industries seeking reliable and efficient vacuum technology.

Republic Claw Pumps are able to deliver superior vacuum performance at much higher efficiencies than many other comprable vacuum technologies. The innovative claw design ensures optimal air compression and reduced energy consumption, making Claw Pumps an energy-efficient solution for your industrial needs. This high efficiency helps reduce operational costs while maintaining excellent performance.

Additionally, Republic Claw pumps have minimal maintenance requirements. The non-contact design of the claws ensures low wear and tear, resulting in extended service intervals, reduced down-time, and lower maintenance costs. Built with robust materials and precision engineering, Republic’s Claw Pumps are designed to withstand the most demanding industrial environments. The durable construction ensures long-lasting performance, even under continuous and heavy-duty use. This durability makes them ideal for applications requiring consistent and reliable vacuum solutions.

Performance Ranges

- Air Flow: 79cfm to 203cfm

- Vacuum: Up to 28"HgV

Available Options

- Inlet filter

- Vacuum gauge

- Explosion-proof motors

- Washdown motors

- Motor starter

- Variable Frequency Drive (VFD)

- To-Spec PLC Panels

- Rotary Claw Central systems

Advantages

- Robust & efficient performance

- Energy efficient

- Contact free

- Steady performance

- Virtually no maintenance

- Minimal downtime

![]()

Industrial

- Robotics

- Pneumatic conveying

- Degassing

- Drying / Evaporation

- Encapsulation

- Vacuum oil purification

- Woodworking

Vacuum hold down

- CNC routing

Central Vacuum Systems

Medical & Laboratory

- Medical Central Vacuum Systems

- Surgery Center at-point Vacuum

- Dental

Food & Packaging

- Vacuum packing

- Forming

- Blister

- Foil handling

- Carton erection

- Pick & place

- Thermoforming

- Packaging

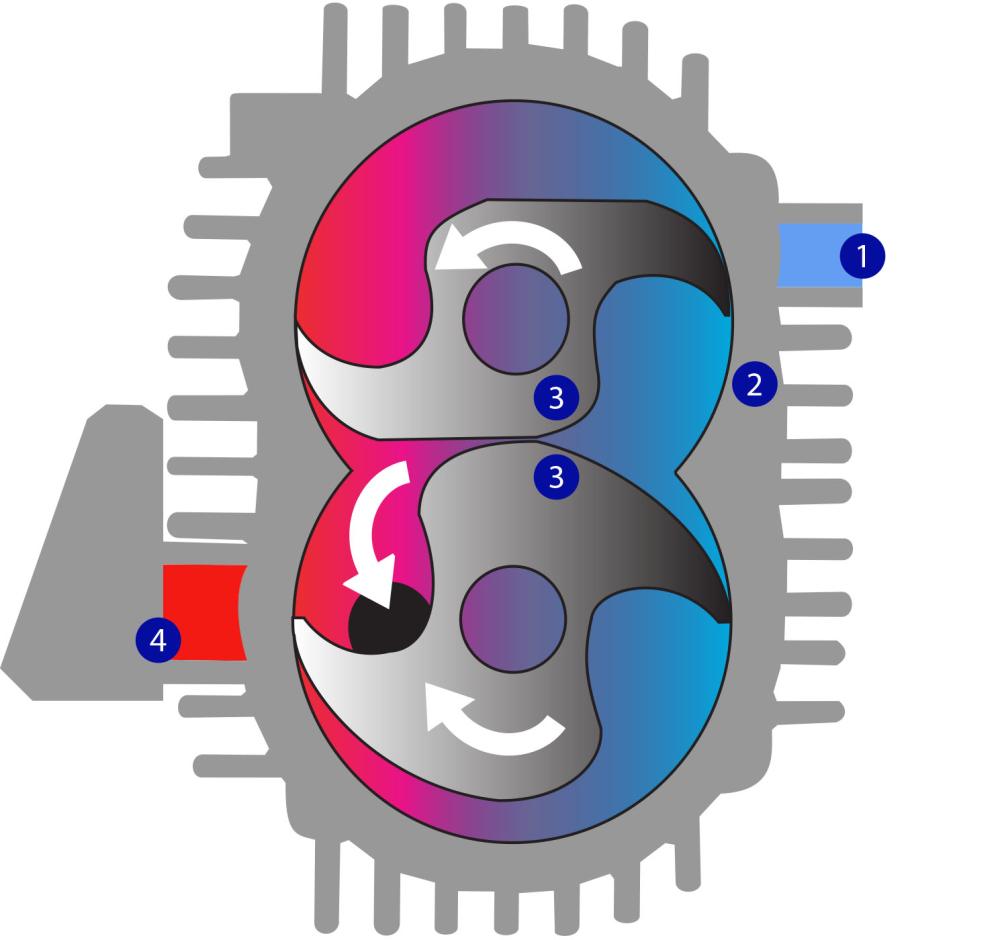

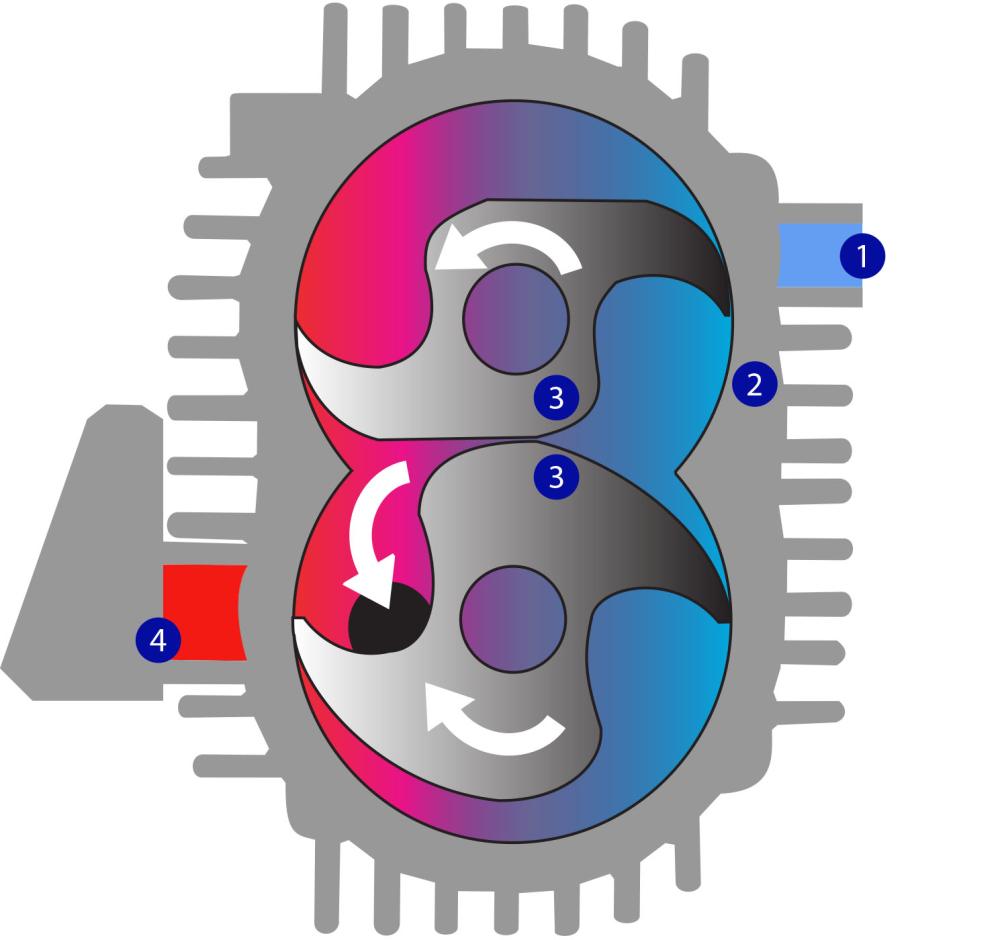

HOW DOES A CLAW PUMP WORK?

Rotary claw vacuum pumps are dry, positive displacement pumps that consist of a pumping chamber (2) and two counter-rotating, synchronized, non-contacting claws (3).

Step 1: The gas enters through the inlet (1) where the gas is filtered by the inlet screen. The gas enters the pumping chamber (2). The precisely-dimensioned claws (3) rotate.

Step 2: The small gap between the claws compresses the gas such that the inlet side has a lower pressure and the high pressure is on the discharge.

Step 3: The oil-free gas is then discharged through the silencer (4).

•The Republic RCV-62c directly replaces Airtech model VCX60.

•The Republic RCV-82 directly replaces Airtech model VCX100c.

•The Republic RCV-302 directly replaces Airtech model VCX305.

•The Republic RCV-402 directly replaces Airtech model VCX405.

•The Republic RCV-502 directly replaces Airtech model VCX515.