Air Knife Systems for Industrial Can Drying

There are a variety of can-drying options available to food, beverage, and other producers, including compressed air, can tunnels, and even hand drying. However, our engineers’ testing and experimentation has shown that the most effective and economical solution by far is an air knife system powered by a centrifugal blower.

The precision and velocity of air knives paired with the energy-efficiency of centrifugal blowers provides an unparalleled system that removes up to 99.9% of liquid, dust, and debris from cans to prepare them for filling, labeling, printing, packaging, and more. Utilizing advanced technology, these systems offer high-velocity and high-impact solutions for drying cans without leaving any residual moisture or debris behind.

In particular, centrifugal blowers and air knives are more efficient and cost-effective than compressed air, which makes a big impact on canning operations that process hundreds or even thousands of cans per minute. Learn more about the advantages of air knives and blowers here.

Solutions for Drying Cans

When paired with a sufficiently powerful blower, air knives produce high-velocity, high-impact air streams that shear away dust, debris, and liquids left behind by wash, rinse, or product filling processes.

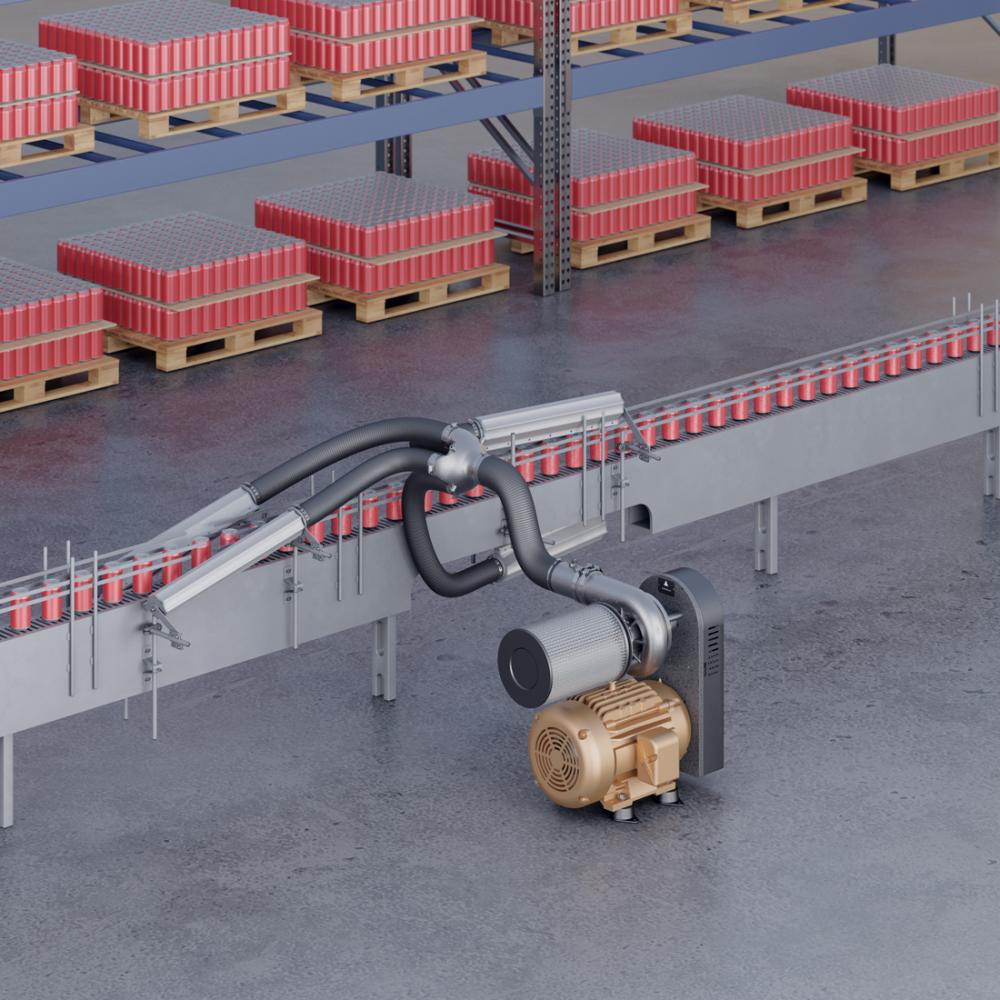

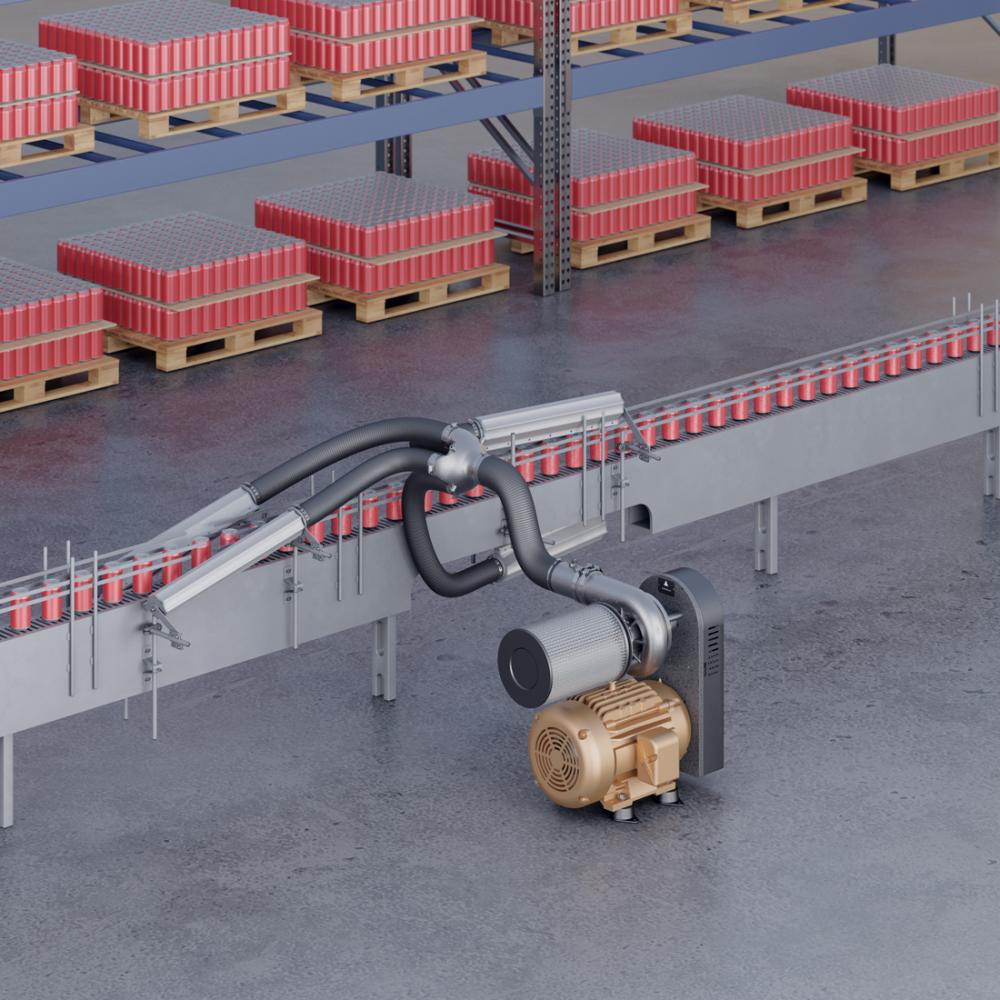

The Republic Air Knife System produces a high velocity, high impact air stream which removes dust, debris and liquids typically found following a wash, rinse or product filling operation. Republic Manufacturing works with a diverse portfolio of different beverage companies from Kombucha, canned wine, craft breweries, and much more. Our systems can be customized to fit your specifications.

Moisture removal to avoid water spots

Moisture removal to avoid smeared printing

Moisture removal to avoid packaging damage and water hazards

How Republic Builds Can Drying Systems

Our can drying systems are engineered, manufactured and tested to provide moisture and debris removal from products prior to labeling, ink jet laser coding, packaging or other secondary operations. These turnkey packages are engineered to meet the specifications and needs of your system and carefully sized to ensure efficient air movement from the blower to the conveyor.

Republic Air Knives are installed on both sides of the conveyor line using adjustable mounting brackets to remove water from the sides of the cans.

The Republic Air Knife positioned directly above the top forces water off and away from the can during the drying process.

Republic Air Knife Systems are sized complete with accessories to ensure no unexpected bends compromise drying results. The angle of the air knives is key to insuring a completely dry can.

Air is piped through either tubing or PVC hose to minimize friction, allowing for optimal flow and pressure. Flexible hose options are available for sharp turns.

Republic manufactures manifolds and Y-branches that allow a single blower to power multiple air knives.

The fully adjustable Air Knife Brackets keep the air knives stable during the drying process.

Republic Centrifugal Blowers are available with a variety of motor/pulley combinations for custom solutions. Enclosures are available for blower protection from wet environments or to provide additional noise control.

Republic also offers standard air knife systems designed explicitly for can drying.