Accurately Sizing A Centrifugal Blower

Republic will get this question a lot, “Is your RB1200 big enough for…?” For many, this seems like a fair question when inquiring about a centrifugal blower for purchase. On the contrary, there are several details that you should focus on when selecting your pump. We’ve compiled a list of three criterion that will help you find the right blower for your application.

While Republic offers a well-established lineup of centrifugal blowers, ranging from a shoe-box-sized RB500 to the half-ton RB4000, “big enough” is not always the right question. There are several questions to be asked, each taking into consideration the nature of the application and the physics of moving air.

There are several questions to be asked, each taking into consideration the nature of the application and the physics of moving air.

Sizing the appropriate blower is a three-step process.

- Understand and characterize the system.

- Select a design point.

- Select a blower that can operate at that design point.

For the sake of this post, an aerodynamic system is the piping into or out of the blower. Each length of tubing or pipe, elbow, valve, and nozzle affects this system. A customer may have, for example, a nozzle with which to blow chips from machined parts. The system, in this case, is the inlet to the blower (usually covered by a filter canister), the blower itself, and tubing or hose from the blower to the nozzle. Each component has a resistance, similar to an electrical circuit, that robs some pressure from the system. Valves, nozzles, and elbows tend to have high resistance, while hoses and conduits have low resistance.

Each component has a resistance, similar to an electrical circuit, that robs some pressure from the system. Valves, nozzles, and elbows tend to have high resistance, while hoses and conduits have low resistance.

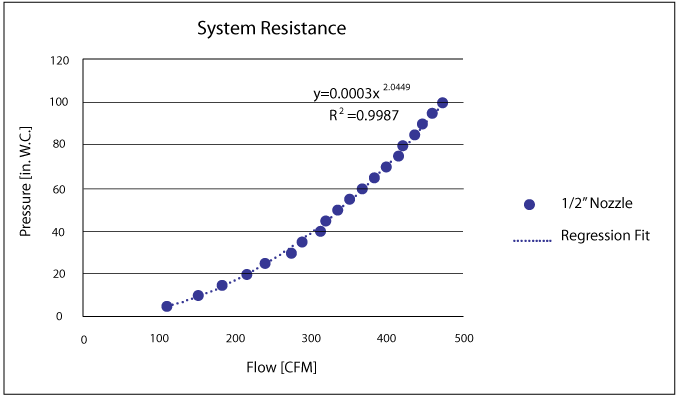

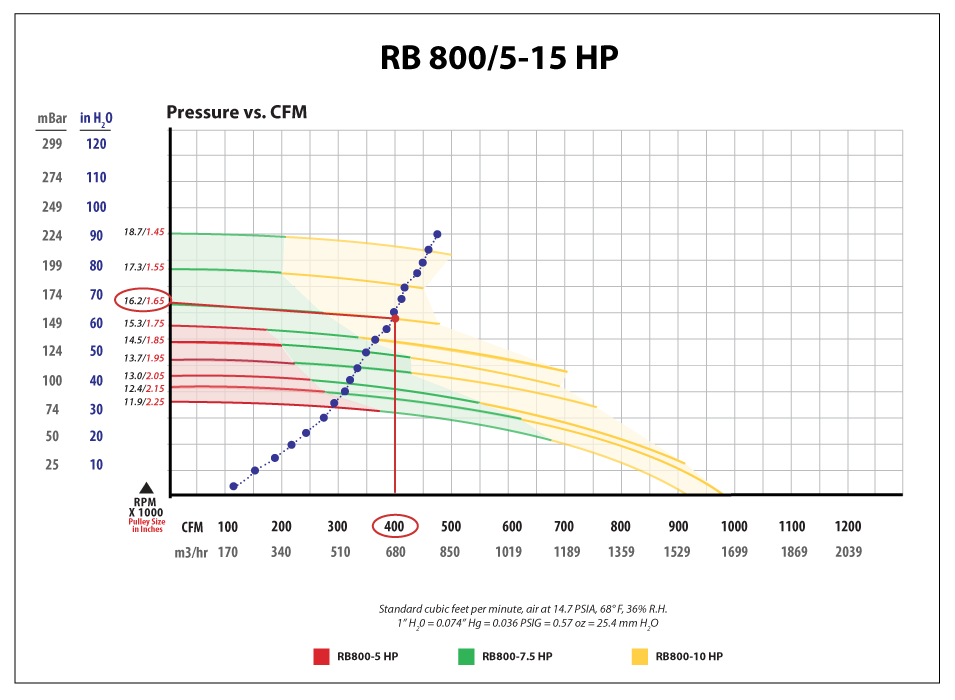

In most cases, a big enough and short enough hose is used that it can be disregarded. The nozzle becomes the main focus. Through testing, the resistance for the nozzle can be plotted on a graph of flow and pressure. Republic has this data for all our nozzles and air knives, allowing us to accurately size these systems. Shown below is a typical test result for an array of ten ½” diameter nozzles. As shown, resistance is usually approximated well by the form Pressure = C (Flow2) for inlet pressures less than 15psig.

If the end user desires a total system output of 400CFM, this graph clearly shows a target pressure of around 70 inches water column is required. This is our design point, the second element in selecting a system. By working to understand the system well, the design point is easy to find.

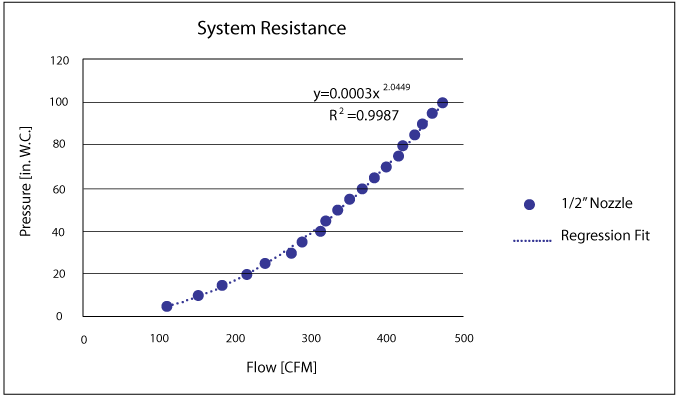

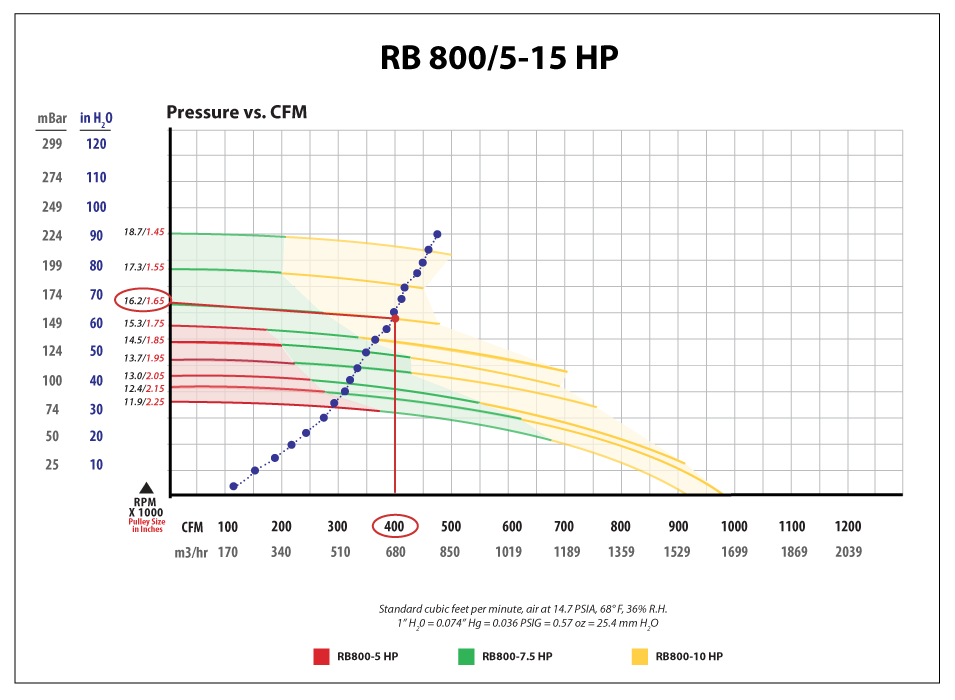

The third step is selecting the blower. By overlaying this curve on a published blower performance curve, the goal becomes simply selecting the point of intersection. Below is the curve for Republic’s RB800 blower, with the system resistance superimposed over-top.

Tracing up from 400CFM, the curves intersect in the yellow range, indicating a 10HP motor is necessary, closest to the line for 16,200rpm (a 1.65 pulley), as noted on the vertical axis. This indicates that, for the given 10-nozzle system, a 10HP RB800 with a 1.65 pulley will stabilize around 400 CFM and 70 inches water column.

As the system gets more complex, whether by adding manifolds, exchangers, etc. or valves and gates, the resistance curve will change. Also, if the blower is working in a different environment (low atmospheric pressure from high altitudes, or moving a gas other than air), the blower performance curve shifts. Republic has trained sales staff and engineers able to assist in specifying the correct blower for these unusual environments, and several years of experience doing so.

Written by: Nathan Wilson