Choosing the Right CNC Vacuum

May 03, 2022

When choosing a CNC vacuum, some commonly asked questions pertain to vacuum strength, durability, and which type to use for different applications. At Republic Manufacturing, we can answer those questions and also point you in the right direction when choosing which CNC vacuum is right for you!

What determines which CNC vacuum is the best?

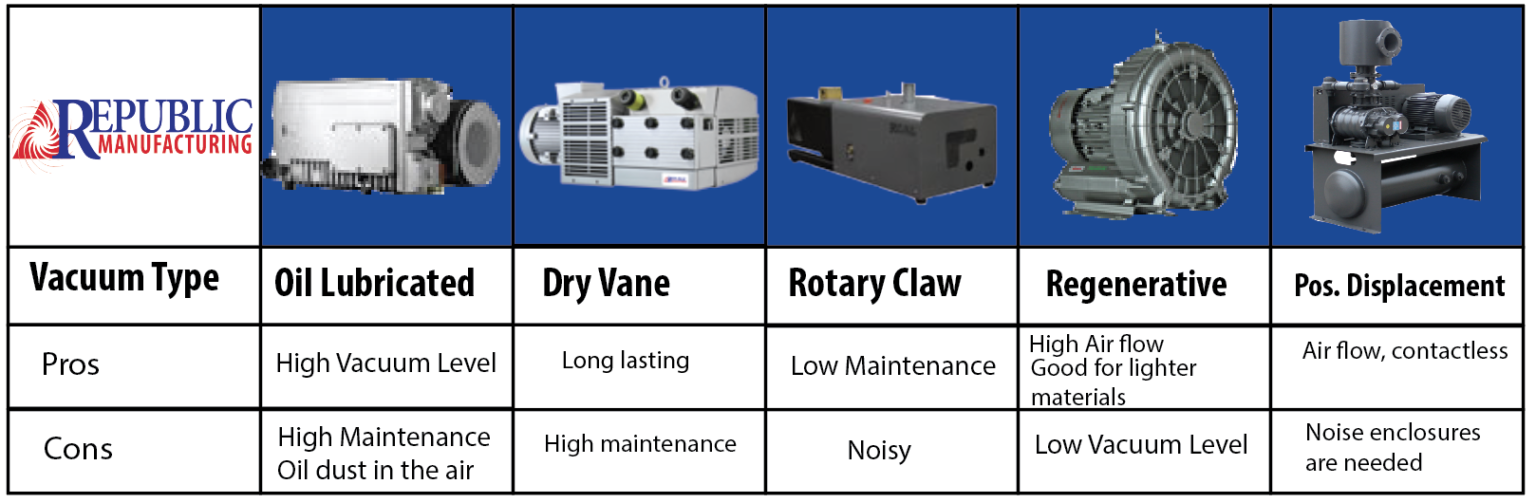

Several factors come into play when deciding which CNC vacuum hold-down is the best. Oil lubricated pumps have the highest vacuum level, while the technology of the rotary claw pumps and the dry vane pumps allows for an even level of vacuum and air flow. High vacuum pressure holds down the surfaces of products, so heavier products require higher vacuum levels. Random shape cutting causes a higher air flow, so the type of pump used must have a lower pressure pump. For example, wood and aluminum when cut allow for more air flow. For this type of job, a regenerative blower or Positive displacement pump would be efficient. Consider these when choosing a CNC vacuum:-

- Size of materials

- Cost

- Preferred maintenance (high or low)

- Table sizes

- Vacuum strength and air flow

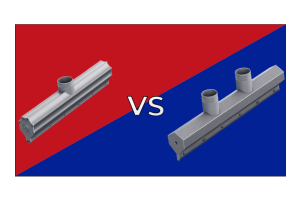

Sign Shops

Sign shops cut anything from wood, brass, foam, to PVC and acrylic. For these types of applications, you can use a larger table size with lighter materials. Regenerative blowers and Positive displacement pumps are used on lighter materials. These pumps have less vacuum strength because the material does not require a lot of pressure to hold it down. You can utilize these functions for random shape cutting.Woodworking

Woodworking works with heavier materials. Dry vane and Claw pumps utilize a higher vacuum level, (25.4inHg, 24inHg) which keeps the heavy material sealed down. If a consumer is working with small and/or expensive materials, a higher vacuum level is required. Oil lubricated vacuum pumps have the highest vacuum strength, but they excrete oil in the air. If you need a high vacuum level pump, then the tradeoff is a higher maintenance tool.How We Can Help You

Have any other questions about which CNC vacuum is right for you? Contact our experts.