4 Top Woodworking Vacuum Questions Answered

August 28, 2023

Vacuum Hold Down for Woodworking: You've got questions. We've got answers.

Woodworking is a complex and demanding industry requiring efficient and reliable equipment. Regarding vacuum systems, the most popular options are regenerative blowers, rotary dry vane pumps, and dry rotary claw pumps. This blog post will address the questions we hear most frequently.Q: How much money can I save?

A: One of the main concerns of woodworking companies is energy efficiency and cost savings. Republic Manufacturing’s regenerative blowers and dry rotary vane claw pumps address these issues by design. Regenerative blowers with VFD (variable frequency drive) and pressure transducer technology can help reduce energy consumption significantly. Using a smaller motor and only running the RPM required for the pressure; regenerative blowers can save energy and reduce costs compared to traditional blowers. This technology allows the Regenerative Blower to use a smaller motor and run only the required RPM for the pressure, resulting in reduced energy consumption and cost savings. Regenerative blowers are maintenance-free - only a filter to change! Dry rotary vane claw pumps use smaller motors which consume less energy, resulting in lower energy consumption and cost savings. This technology is nearly maintenance-free - no vanes or oil to change! The only maintenance parts on a claw pump are roughly one quart of gear oil and an inlet filter. These products have minimal wearing and maintenance parts, reducing maintenance and repair costs and making them an attractive option for companies looking to optimize their operations.Q: What makes vacuum better than clamps?

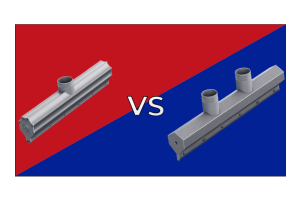

A: Vacuum hold down is a more technological way to secure product to the table during cutting. While clamps work for some smaller tables, a vacuum pump can benefit any table larger than 3 feet. Clamps do not provide uniform hold down. While cutting the material, the product will begin to shift. Vacuum, however, provides constant, consistent suction, securing the material across the entire table. You’ll get enhanced precision and accuracy, increased efficiency, and better safety at the click of a button.Q: Do dry rotary vane pumps work well?

A: Yes. BUT… dry rotary vane pumps are the technology of yore. Long a standard for woodworking applications, the dry rotary vane pump is considered the workhorse of the industry. Will they work? Yes, but at what cost? The inner workings of dry rotary vane pumps - where the vanes rotate, scrapping along the chamber to create the vacuum - naturally create friction. The extra friction requires the pump to utilize more horsepower to operate. In addition, the vanes naturally wear, requiring replacement every 3000 hours or at least once a year. Vanes are costly. And, if not changed in time, they can break, causing catastrophic pump failure. Republic Manufacturing offers a full range of dry vane vacuum pumps suited well for the woodworking industry. They are easy to install and operate as a direct replacement for many of the other brands. Vanes, gaskets, filters, and other replacement parts are available. So if dry rotary vane technology is your comfort zone, we’ve got you covered. If you are interested in other technologies listed above, we are happy to work up an estimated return on investment.Q: What if I’m interested in switching to a new pump technology?

A: No problem! Contact us, and we will address your needs to ensure you use the best technology for your application. We will review the following:- Vacuum and flow requirements based on table size, material, elevation, and cut sizes.

- Power availability.

- Connection sizes.

- Any other pertinent information.