Optimizing Airflow in Printing: The Power of Regenerative Blowers & Rotary Vane Pumps

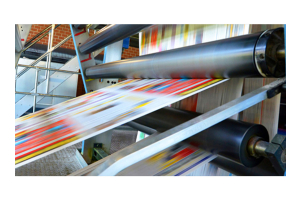

The print and paper industry relies on precision and efficiency at every stage of production. From paper handling to ink drying, maintaining proper air movement is crucial to ensuring high-quality prints and smooth operations. Republic Manufacturing specializes in advanced air movement solutions, including regenerative blowers and dry rotary vane pumps, which help printing and paper manufacturers enhance efficiency, reduce waste, and improve product quality.

The Role of Air in the Print & Paper Industry

Air plays a vital role in ensuring seamless production processes in printing and paper handling. Common applications include:

- Sheet and Web Handling: Ensuring paper moves smoothly through printing presses without misalignment.

- Ink Drying and Curing: Controlling drying time to prevent smudging and ensure crisp prints.

- Dust and Debris Removal: Preventing contamination that could affect print quality.

- Vacuum Hold-Down: Keeping sheets in place for precision printing and finishing processes.

Without reliable air movement and vacuum systems, manufacturers face challenges such as paper jams, misfeeds, ink smudging, and inconsistent print quality.

How Regenerative Blowers Work in Printing & Paper Applications

What is a Regenerative Blower?

Regenerative blowers generate a high-volume, low-pressure air stream, making them ideal for non-contact applications. They operate oil-free, require minimal maintenance, and are highly energy-efficient.

Applications in Printing & Paper

- Sheet Separation & Feeding: Prevents multiple sheets from feeding at once, ensuring smooth paper movement.

- Air Knife Drying: Used for ink drying and coating applications, providing even drying to improve print durability.

- Dust & Debris Removal: Removes contaminants that could interfere with print quality.

Key Benefits of Republic’s Regenerative Blowers

- Energy-efficient operation with minimal maintenance.

- Compact and lightweight, making them easy to integrate into production lines.

- Oil-free design, ensuring a clean operating environment.

How Dry Rotary Vane Pumps Enhance Printing Efficiency

What is a Dry Rotary Vane Pump?

A dry rotary vane pump generates a consistent vacuum without the need for oil, making it an efficient and low-maintenance solution for vacuum-dependent processes.

Applications in Printing & Paper

- Vacuum Hold-Down for Sheet-Fed Presses: Keeps sheets securely in place during high-speed printing.

- Material Conveying & Stacking: Ensures smooth movement of paper through finishing processes.

- Perforation, Binding, & Trimming: Helps maintain precision by securing paper during finishing operations.

Key Benefits of Republic’s Dry Rotary Vane Pumps

- Quiet, oil-free operation, reducing maintenance needs.

- Consistent vacuum pressure, preventing paper misfeeds and misalignment.

- Longer service life, leading to cost savings over time.

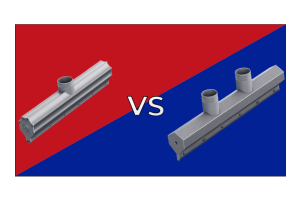

Comparing Regenerative Blowers & Dry Rotary Vane Pumps in Printing

| Feature | Regenerative Blower | Dry Rotary Vane Pump |

|---|---|---|

| Function | Airflow & pressure | Vacuum suction |

| Common Use | Ink drying, dust removal, sheet separation | Paper hold-down, material transport |

| Maintenance | Low, oil-free | Low, minimal moving parts |

| Efficiency | High-volume air movement | Precision vacuum control |

| Application Examples | Web presses, drying stations | Sheet-fed presses, stacking |

Why Choose Republic Manufacturing for Your Printing Air Solutions?

Republic Manufacturing has decades of experience in designing custom air movement solutions tailored to the printing and paper industry. Here’s why manufacturers trust our technology:

- Industry Expertise: Proven track record of improving efficiency in printing operations.

- Energy-Efficient Solutions: Designed to reduce operational costs while improving performance.

- Custom Configurations: Tailored air systems to fit unique production line requirements.

- Reliable Support & Service: Expert guidance and maintenance support for long-term performance.

The right air movement solutions can significantly enhance efficiency, quality, and reliability in printing and paper production. Whether it's drying ink, securing sheets, or controlling dust, Republic Manufacturing’s regenerative blowers and dry rotary vane pumps provide the performance and reliability businesses need to stay competitive.

For expert consultation on optimizing your printing air systems, contact Republic Manufacturing today.