Centrifugal Blowers

Republic Centrifugal Blowers (RB & RBX Series) are belt-driven and designed for both pressure and vacuum applications, and are engineering to generate flow up to 4,100 cfm and pressure greater than 160 in.H2O. Republic Centrifugal Blowers are preferable to compressed air as centrifugal blowers provide clean, dry, oil-free air at lower operating costs.

Both the RB and RBX series were built for longevity in high-duty applications and require minimal maintenance. Each blower is manufactured with lifetime greased ceramic hybrid bearings and plated steel or aluminum alloy wetted components. Each model can be oriented in multiple directions, assembled within sound or weather enclosures, or converted to water-cooled and/or chemically resistant packages.

The RB-Series has decades of proven performance across a wide spectrum of applications and industries, while the best-in-class RBX-Series attains 80% peak efficiencies, consume less power, utilize smaller motors, and require fewer replacement assemblies. The RBX-Series also offers up to 8 times longer bearing life than the competition and comes with a standard two-year warranty.

Performance Ranges

- Air Flow: 500 to 4,100 cfm

- Pressure: Up to 170" H2O

- Vacuum: Up to 130" H2O

- Power Options: 3-75 Horsepower

- Operating Speed: ≤ 25,000 rpm

Available Options

- Enclosures (Sound + Environmental)

- Explosion-proof motor

- Washdown motor

- IEC or NEMA Premium motor

- Stainless steel construction

- Inlet and outlet flanges

- Water-cooled

- Chemically resistant seals

Advantages

- 10-Groove belt for long life

- Ceramic hybrid bearings

- PTFE shaft seal on both sides of bearing assembly

- Rotatable discharge

- Stainless steel blower pulley, zinc plated steel motor pulley, and steel motor housing

- 6061 T6 aluminum impeller (RBX-Series)

- Easy to remove bearing/impeller housing for quick replacement

- 100% Operational performance and vibration tested

Accessories

- Exhaust silencer

- Starter panel

- Variable frequency drive

- Blower Stands

![]()

Beverage

- Product drying

- Crate cleaning and drying

Bakery

- Excess product removal

- Belt cleaning

- Dust removal

- Pan, tray and board cleaning and drying

Medical

- Drying products

- Excess product removal

- Belt cleaning

- Dust removal

- Prevent product slippage

Chemical Processing

- Belt cleaning

- Product drying

Food

- Drying products

- Excess product removal

- Belt cleaning

- Dust removal

- Pan and tray cleaning and drying

Pharmaceutical

- Dryiing product packaging prior to ink jet coding or labeling

- Drying of vials, syringes, sterile packs, pouches, tubes, trays, crates, and pallets

- Drying of mising and storage tanks

- Drying under the cap or lid

- Debris removal

- Moisture removal

- Dust removal

- Conveyor belt blow-off

- Leveling coating on caplets

Centrifugal Blowers are the perfect solution for vacuum applications or as a more efficient and cost-effective alternative to air compressor systems. Centrifugal blowers provide dry, clean, oil-free air and require low energy consumption. Unlike compressed air systems, centrifugal blowers run at low pressure and enable much faster production speeds without the safety risk of high-pressure systems. Republic Centrifugal Blowers, including the RBX and the original RB series, come with ceramic hybrid bearings, rotatable outlet discharge, easy to remove steel bearing housing assembly, and zinc planted steel motor pulley. Options include explosion proof motors, washdown motors, and IEC or NEMA Premium motors. See our full lineup of Republic Centrifugal Blowers below, with output, pressure, and power specifications for each unit.

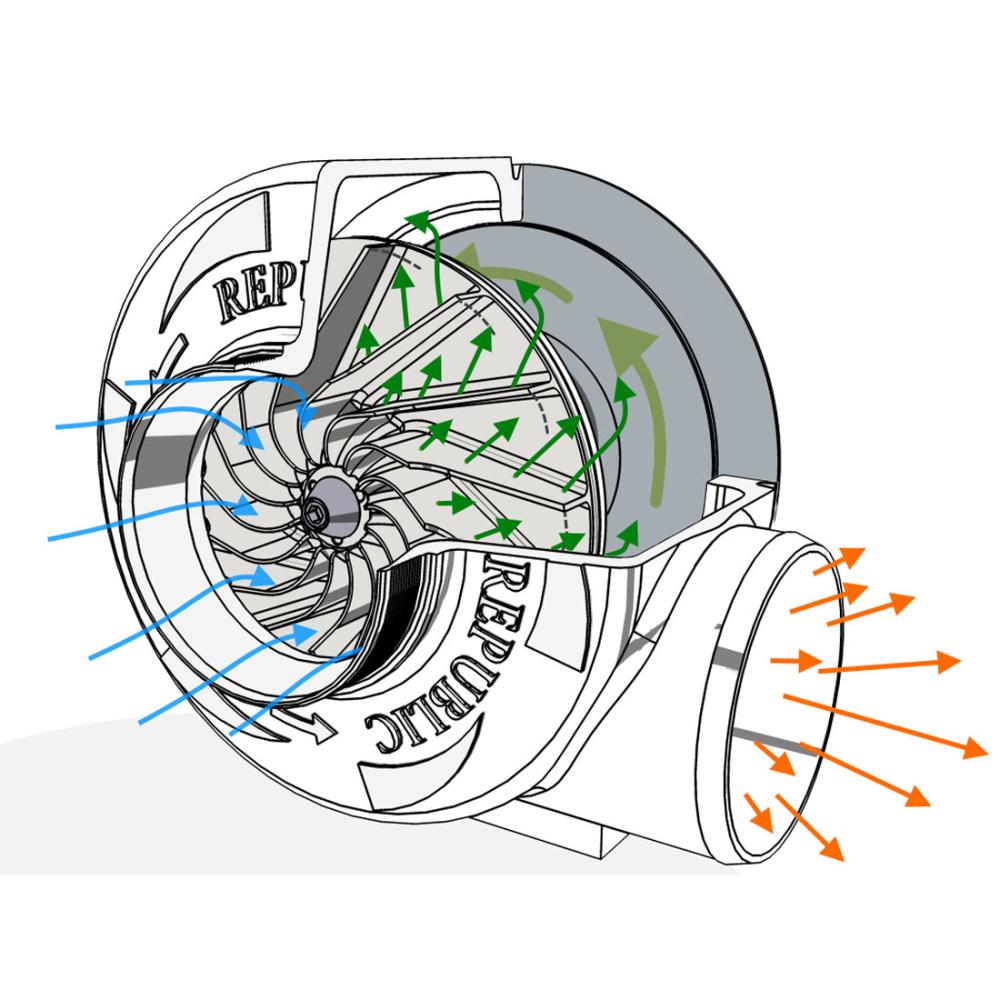

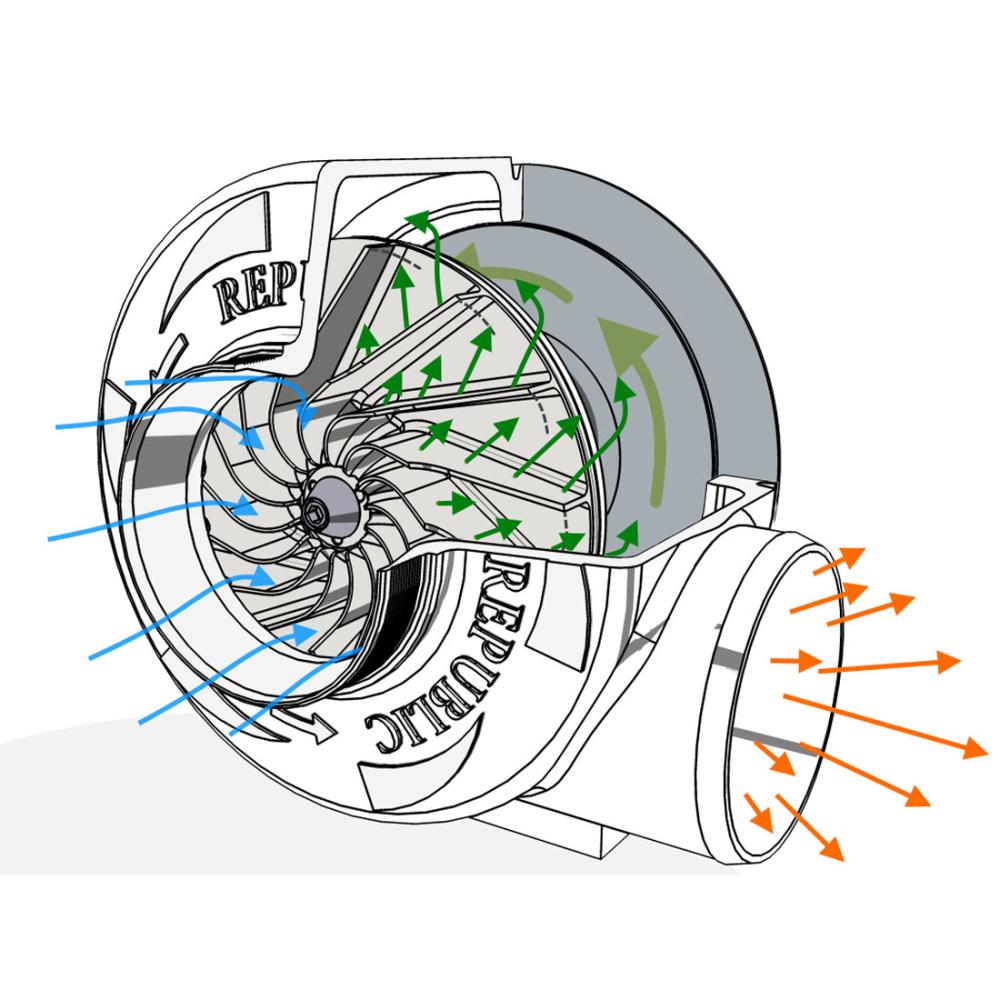

HOW DOES A CENTRIFUGAL BLOWER WORK?

Air enters the centrifugal blower's spinning impeller and is divided between the impeller's vanes. As the impeller turns, it accelerates the air outwards using centrifugal force. This high-velocity air is then diffused and slowed down in the surrounding blower housing to create pressure.