Dry Vane Vacuum Pumps

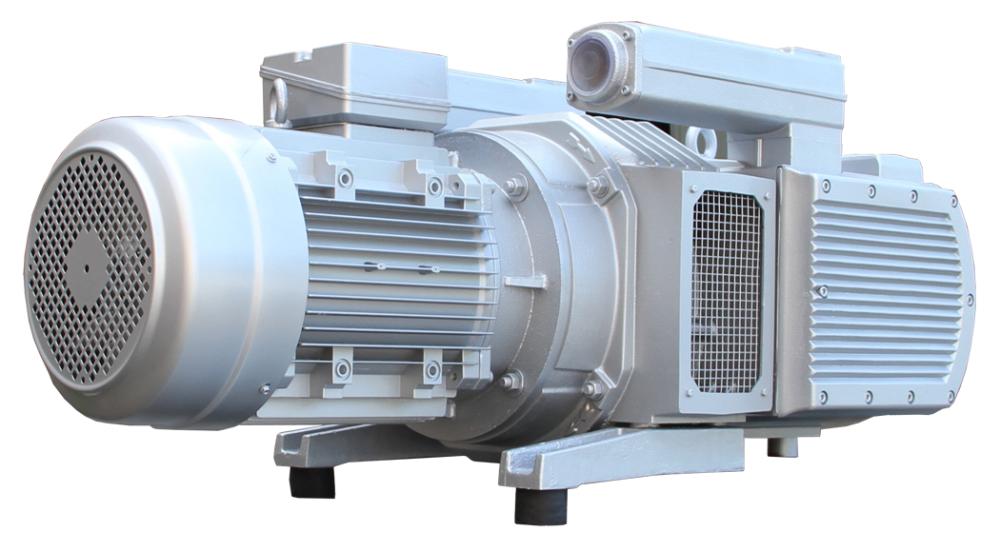

Dry Rotary Vane Vacuum Pumps for Oil-Less Applications

Republic offers Dry Rotary Vane Pumps that are ideal for applications requiring clean and reliable vacuum, such as packaging, medical, and food processing. Republic's Dry Vane Pumps can pull a maximum of 25.5” HgV. Republic's VRT series dry vane pumps are single stage, dry-cooled and direct driven for continuous operation.

Air Flow: From 5 cfm up to 177 cfm

Vacuum Capacity: Up to 25.5" HgV

Available Options

- Specialty motors

- Central systems

- Variable frequency drives

- Custom panels

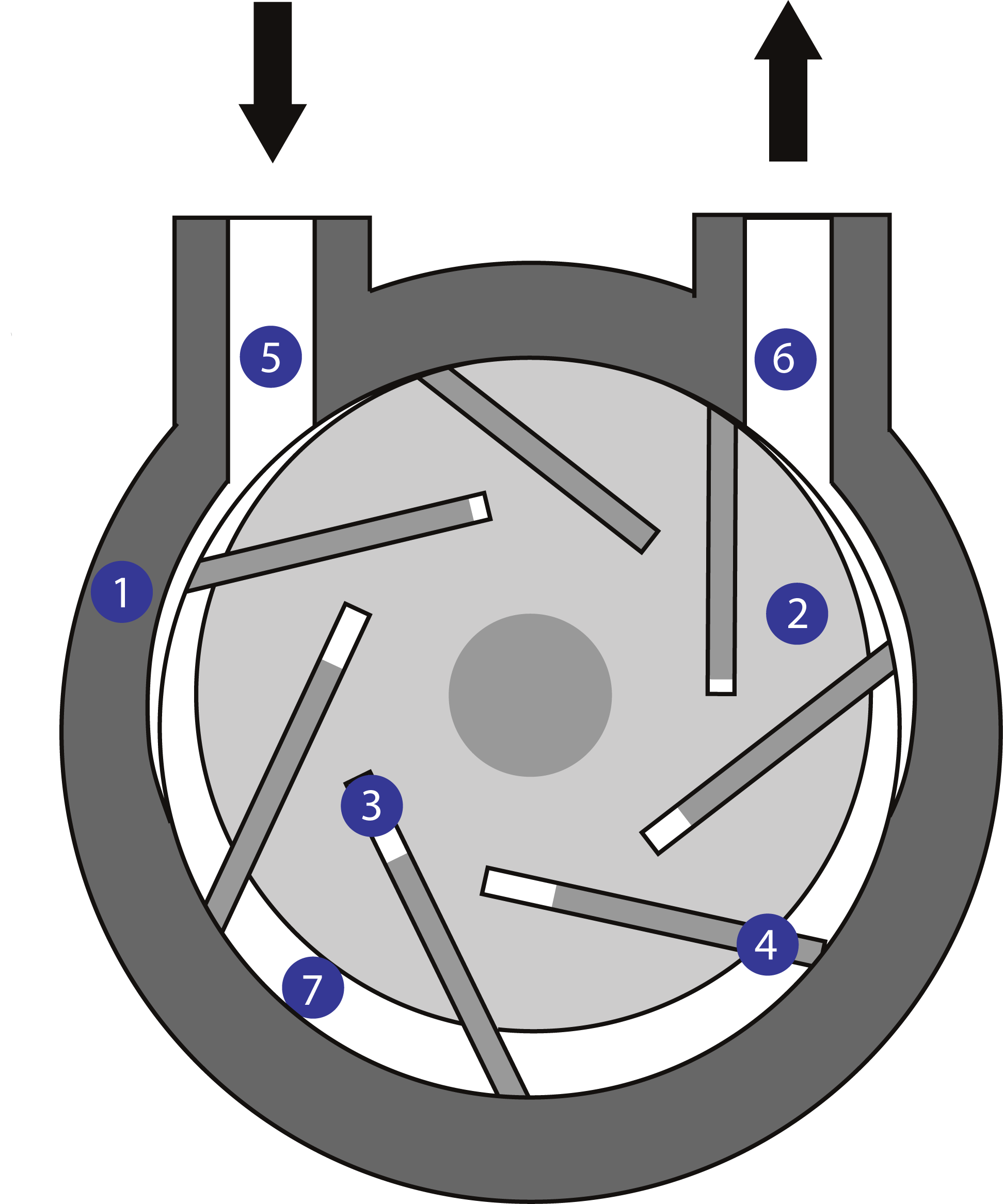

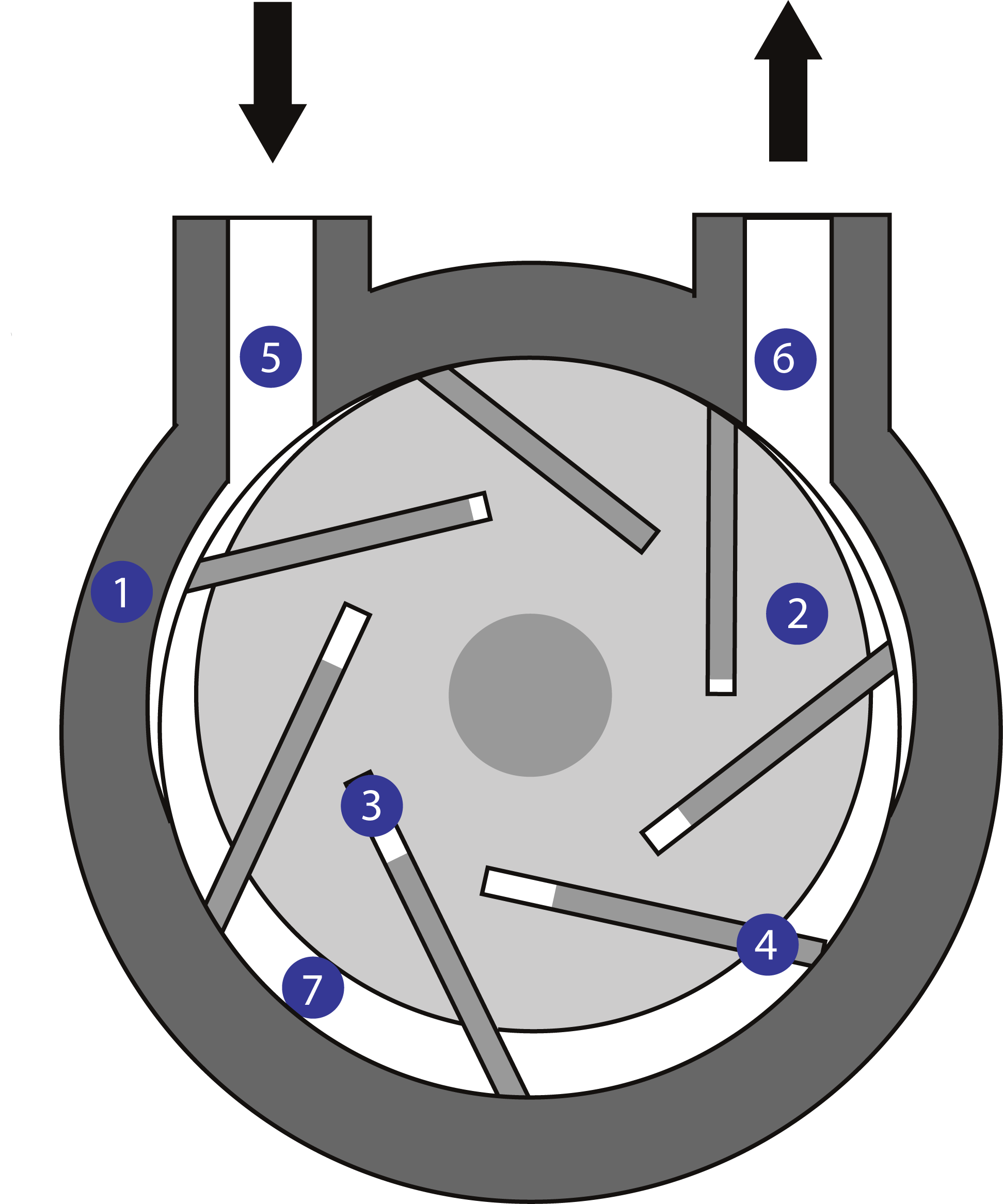

Rotary vane pumps consist of a cylindrical housing (1), eccentrically positioned rotor (2), and numerous free-moving vanes (4). The vanes are placed in the slots of the rotor (3) and, as the rotor turns, the centrifugal force throws the vanes against the cylindrical wall, creating multiple chambers between the rotor, the vanes, and the cylinder (7). The chamber volume changes as the rotor turns. From the inlet port (5), the chamber volume enlarges, and then decreases towards the outlet port (6). As air enters the inlet port (5) and the chamber enlarges (7), the vanes create a vacuum. As the air is pushed through the chamber and it becomes compressed, pressure is produced at the outlet port (6).

How does a vacuum pump work?

Vacuum pumps create a low-pressure environment by drawing air from a vacuum chamber or region into another chamber, reducing the density of air particles in the vacuum chamber and creating a pressure gradient. This mechanism can be used in applications where air needs to be moved, since the air particles will flow from high to low pressure areas, or where a low-pressure environment needs to be maintained, such as in drying applications or pick-and-place.

What is a dry pump?

A dry pump is a pump that operates without any oil in the vacuum chamber, which prevents contamination of the process gas. Claw pumps are popular in applications that require a dry or oil-free environment. Since the claws come into very close proximity but do not touch, claw pumps do not require oil in the vacuum chamber

Food & Packaging

- Vacuum packing

- Forming

- Blister

- Foil handling

- Labeling

- Carton erection

- Pick & place

Industrial

- Robotics

- Vacuum hold down

- CNC tables

- Pneumatic conveying

- Degassing

- Drying

Environmental

- Aeration

- Soil vapor extraction

- Sparging

Central Systems

- Laboratory

- Medical

- Dental

- Process

- Paper handling

- Binding

- Print press